REDUCE IN CARBON FOOTPRINT

As an internationally operating company, employees’ business travel is necessary, while the company seeks to reduce it, for example, by utilising the possibilities of modern technology and by favouring virtual meetings. The travel practice always guides the employees to choose the most environmentally friendly alternative for travel and meetings. Emissions from daily commuting have been reduced by organising bus transportation for personnel at several Scanfil factories. The company’s updated vehicle policy favours low-emission cars, such as hybrid models.

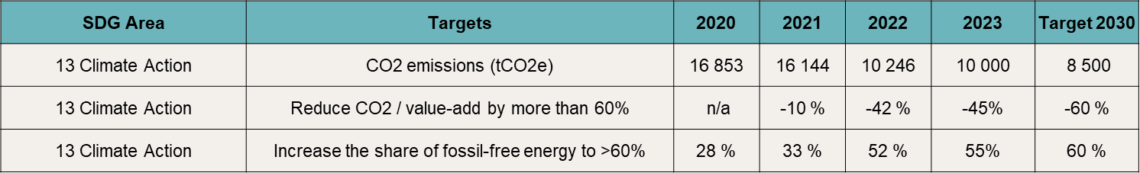

CO2 emission target is aligned with Greenhouse Gas Protocol. Our centric objectives by the year 2030 are as follows:

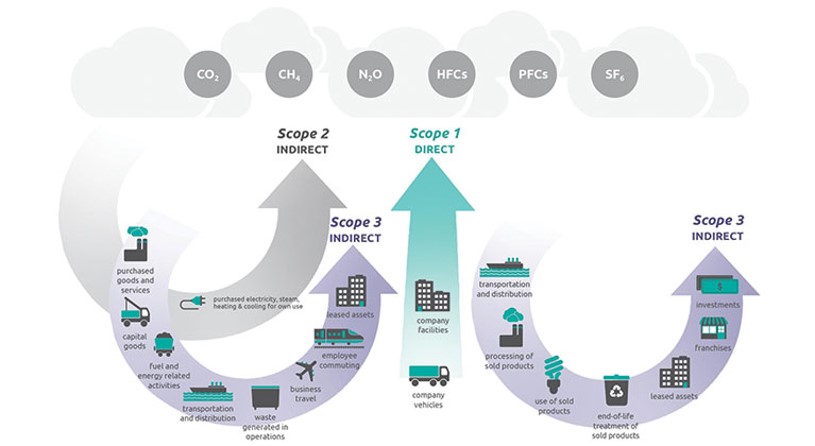

GREEN HOUSE GAS PROTOCOL

Scope 1 – All Direct Emissions from the activities of an organization or under their control. Including fuel combustion on site such as gas boilers, fleet vehicles¹ and air-conditioning leaks.

Scope 2 – Indirect Emissions from electricity purchased and used by the organization. Emissions are created during the production of the energy and eventually used by the organization.

Scope 3 – All Other Indirect Emissions from activities of the organization, occuring from sources that they do not own or control. These are usually the greatest share of the carbon footprint, covering emissions associated with business travel, procurement, waste and water.

ENVIRONMENTAL CERTIFICATE HELD BY ALL

All Scanfil’s factories have a certified ISO 14001:2015 -compliant environmental management system that verifies the measurement and improvement of environmental impacts on the company’s management and employees, as well as on its external stakeholders. The company’s management monitors the implementation of environmental practices, as well as the development of key indicators and

the goals set, both locally and at group level. The employees are provided with the necessary knowledge and training to ensure they can work in accordance with the objectives of our environmental practices.

Scanfil produces extensive services for its customers, ranging from product design and development to product manufacture, material procurement and logistics solutions. Products are designed and manufactured on the basis of customers’ requirements, which means that the design process starts with product data provided by each customer. Accurate data and careful design allow a more efficient manufacturing process and a reduction in the environmental impacts of production. The efficiency of resource utilisation and the environmental friendliness of raw materials and products throughout their lifespans are analysed in detail. Environmental impacts are taken into account throughout Scanfil’s value chain, ranging from the procurement of raw materials to production, distribution and recycling.

Scanfil promotes sustainable development by identifying, measuring and reporting the environmental impact caused by its activities. The goal is to reduce the impact

to the environment. Scanfil’s aspiration is to consider the environmental impact throughout the value chain, ranging from the procurement of raw materials to production, distribution and recycling possibilities. All Scanfil’s factories have a certified ISO 14001-compliant environmental management system. In its production, Scanfil mainly uses metals, components and chemicals. It prefers recyclable

materials and eco-friendly products. Part of the materials to be used are chosen by customers. The utilisation rate of all raw materials is optimised to ensure the efficient use of resources and decrease the amount of waste created. Waste materials are recycled if they cannot be re-used in the company’s own production. Steel is the most important raw material used by Scanfil. Its effective use is closely monitored in the production process. The risks associated with chemicals are analysed before their deployment, and they are handled following precise instructions and precautions. In addition, proper training and drills are arranged to prepare for any accidents.