Committed employees

We know the quality of your product is of utmost importance. Our people are committed to maintaining the highest quality standards in every step of the manufacturing process.

Measured

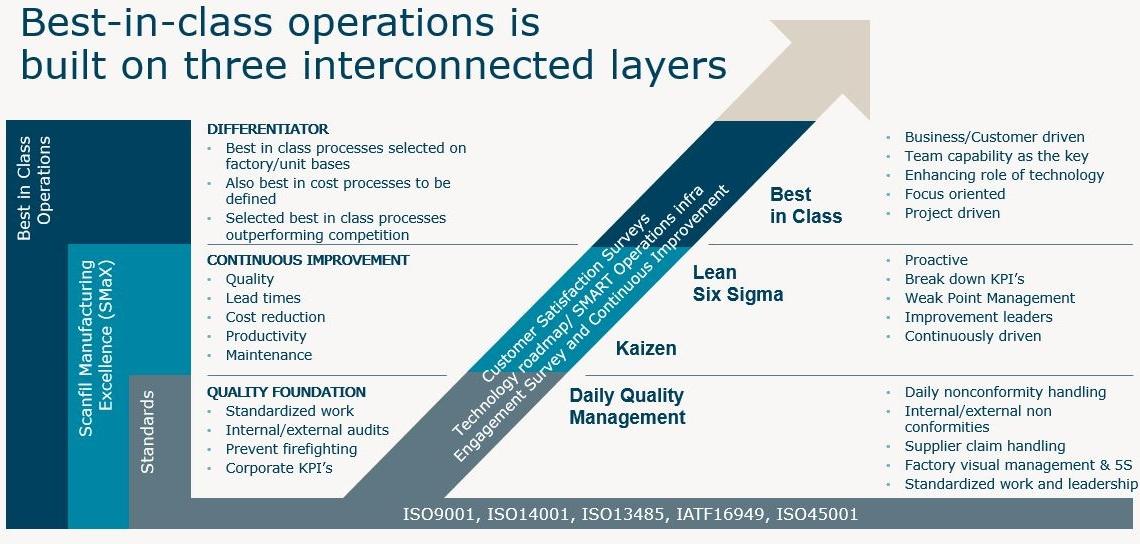

At Scanfil, quality starts from the engagement of the top management and extends throughout the production process and supply chain. We are measuring and developing our operational efficiency and quality following the principle of continuous improvement.

Certified

Each Scanfil facility has a certified ISO 9001-compliant quality management system. Additionally, selected plants have more detailed certified quality management systems aimed at meeting the needs to specific industries. For example, plants that serve medical customer accounts have a certified ISO 13485-compliant quality management system.

Scanfil Quality Certificates

Read moreOptimised

The quality of our operations consists of highly standardised processes and our highly skilled and trained personnel. The internationally recognised Lean Six Sigma process development method is in use at all of our plants, It helps us to optimise our production resources and manufacture products of a consistent quality standard.

Analysed

Scanfil’s high-quality production is completed using a functional quality assurance plan. Our plants use the FMEA (Failure Mode and Effects Analysis) risk evaluation method, which helps us to identify any risk-prone areas in our production. Being aware of potential issues allows us the ability to quickly and efficiently resolve problems.